Enclosure Coating System

Indusmetal Torres products are intended for outdoor use, to be exposed to rain and bad weather. We would like to share our experience in the process of high-quality plastic-coating with powder paint for metal products exposed to the elements. Indusmetal Torres offers the following finishes to improve the durability and appearance of its products.

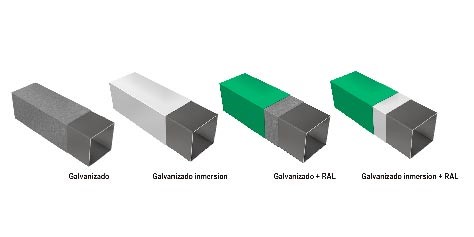

Galv. Finish (Sendzimir Galvanizing), also called continuous galvanizing. Z-275 quality galvanising. Zinc is applied with the piece moving and then blown to give a uniform layer. Optimal properties for corrosive environments.

HDG Finish (Dip Galvanising). Z-400 quality galvanising. Zinc is applied by dipping the piece without moving it. Increased zinc thickness.

It does not look as neat, because of the thickness of zinc. Very good properties for corrosive environments.

Galv. + RAL or HDG + RAL Finish (polyester coated). Powder coating formulated with TGIC-free polyester resins, excellent outdoor durability and good chemical and mechanical properties. Can be applied on Sendzimir galvanised and by dipping. Very good properties for corrosive environments.

ULTRA PROTECTION

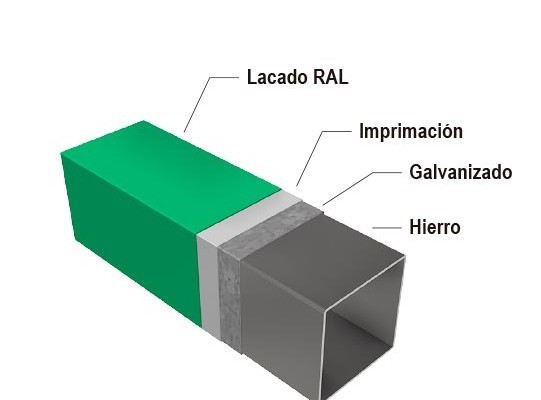

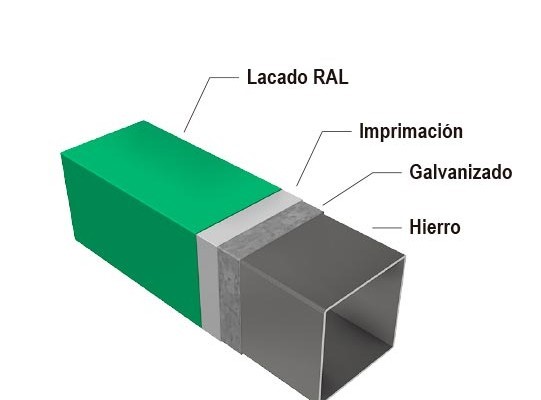

Galv. + Primer + RAL Finish (double plastic-coated, primer + polyester). 1 layer of galvanised + 2 layers of lacquer. 3 layers of maximum protection for our products. Good properties for corrosive environments.

COATING PROCESS FOR METAL ENCLOSURES AND FENCES

- Cleaning the piece: the pieces pass through a washing-degreasing and phosphating tunnel to eliminate any residues and impurities, leaving a perfect surface for the paint to adhere to.

- Application of paint powder: paint is applied using spray guns. These electrostatically charge the dust particles so that they adhere to the piece.

- Polymerising: the powder-coated parts pass through a high-temperature furnace that activates the polymerisation reaction. This reaction causes a progressive hardening of the top layer.

- Quality control: In order to ensure the quality of the coating process, we carry out continuous testing at different stages of the plastic-coating process.

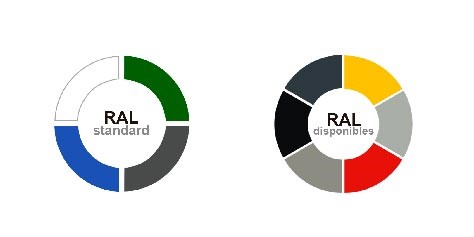

CHOOSING THE RAL CHART COLOUR

Standard colours: blue (5010), green (6005), white (9010) and oxiron.

Available colours: 7016, 1021, 9005, 7030, 3020, 7030

Any RAL chart colour to order.